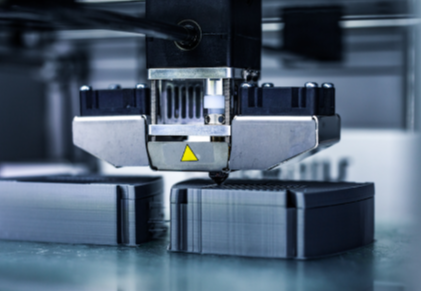

The impact of 3D printing on manufacturing processes is profound. This technology introduces significant design flexibility, allowing for complex geometries and tailored components. Additionally, it minimizes material waste through on-demand production. Various industries, including automotive and healthcare, are increasingly adopting these methods. As sustainability gains importance, the implications of 3D printing extend beyond mere efficiency. Understanding its potential to reshape traditional manufacturing practices reveals critical insights into future industrial trends.

The Evolution of 3D Printing Technology

Although 3D printing technology has roots that trace back to the 1980s, its evolution has been marked by significant advancements that have transformed its role in manufacturing.

The history timeline of 3D printing showcases pivotal milestones, such as the introduction of stereolithography in 1986 and the subsequent development of selective laser sintering in the 1990s.

By the early 2000s, advancements in materials and software began to enhance the precision and versatility of 3D printers. The introduction of Fused Deposition Modeling (FDM) democratized access, allowing broader applications across various industries.

Today, advancements in speed, scalability, and automation continue to reshape manufacturing paradigms, enabling a shift towards more personalized and efficient production methods that align with the growing demand for innovation and freedom in design.

Read more: The Basics of Software Development for Beginners

Key Advantages of Additive Manufacturing

The advancements in 3D printing technology have positioned additive manufacturing as a transformative force in the production landscape.

One of the primary advantages of this approach is cost efficiency, as it significantly reduces material waste and lowers production costs through on-demand manufacturing. Traditional methods often require extensive tooling and setup, whereas additive manufacturing enables rapid prototyping and small-batch production without the same financial burden.

Furthermore, design flexibility is unparalleled; complex geometries that were previously unfeasible can now be realized, allowing for innovations that enhance functionality and performance. This adaptability fosters a creative environment where engineers can iterate rapidly, tailoring designs to meet specific requirements without constraints typically imposed by conventional manufacturing processes.

Applications Across Various Industries

How can 3D printing revolutionize various sectors beyond traditional manufacturing?

This technology has shown significant potential across multiple industries, particularly in the production of automotive parts, where lightweight and complex geometries can enhance vehicle performance.

In healthcare, 3D printing facilitates the creation of custom medical devices tailored to individual patient needs, improving treatment efficacy.

The aerospace sector benefits from the ability to manufacture lightweight aerospace components that meet rigorous safety standards while reducing material waste.

Additionally, custom tooling produced through additive manufacturing allows for rapid prototyping and reduced lead times, optimizing production processes.

Thus, the integration of 3D printing into these sectors exemplifies its transformative capabilities, driving innovation and efficiency in diverse applications.

The Future of 3D Printing in Manufacturing

As advancements in 3D printing technology continue to emerge, the potential for its integration into manufacturing processes appears increasingly transformative.

The future of 3D printing in manufacturing is poised to prioritize sustainability initiatives, allowing companies to minimize waste and energy consumption. This technology enables the production of complex geometries that traditional methods cannot achieve, thus enhancing design flexibility and facilitating the creation of lightweight yet strong components.

Moreover, the ability to produce on-demand reduces inventory costs and accelerates the supply chain, allowing for more agile responses to market demands.

As manufacturers embrace these innovations, the convergence of 3D printing with automation and artificial intelligence will further refine processes, ultimately leading to a more sustainable and efficient manufacturing ecosystem.

Conclusion

In conclusion, 3D printing stands as a beacon of innovation in the manufacturing landscape, illuminating pathways to efficiency and sustainability. Its capacity for customization and reduction of waste reshapes traditional practices, fostering a new era of production. As industries continue to embrace this technology, the potential for transformation is boundless, promising to forge a future where creativity and practicality intersect seamlessly. The evolution of manufacturing is not merely ongoing; it is being redefined, layer by layer.